About a year ago I made a ESP8266 based design for a vibrator development board including IMU, motor driver and battery charging. The design was based on the Adafruit ESP Huzaah, but I used components of Seeedstudio Open Parts Library. This is a library of parts (IC, connector, resistors) which are stocked at Seeedstudio especially for their PCBA (printed circuit board assembly) service. PCBA is really great. Instead of tinkering and soldering on your own you can send the design to Seeedstudio, they make the printed circuit board and assemble all parts. Unfortunately the main part – the ESP8266 microcontroller – was missing in the Open Part Library . So I turned to use the affordable ready-made WeMos ESP8266 boards (see here).

In June 2017 I took a closer look at the PCBA service. At that time the OPL offered two variants of the ESP8266. But even better: You could order almost any part. The difference between using OPL parts and other parts was the time for the assembly as it takes more time to order parts which are not on stock.

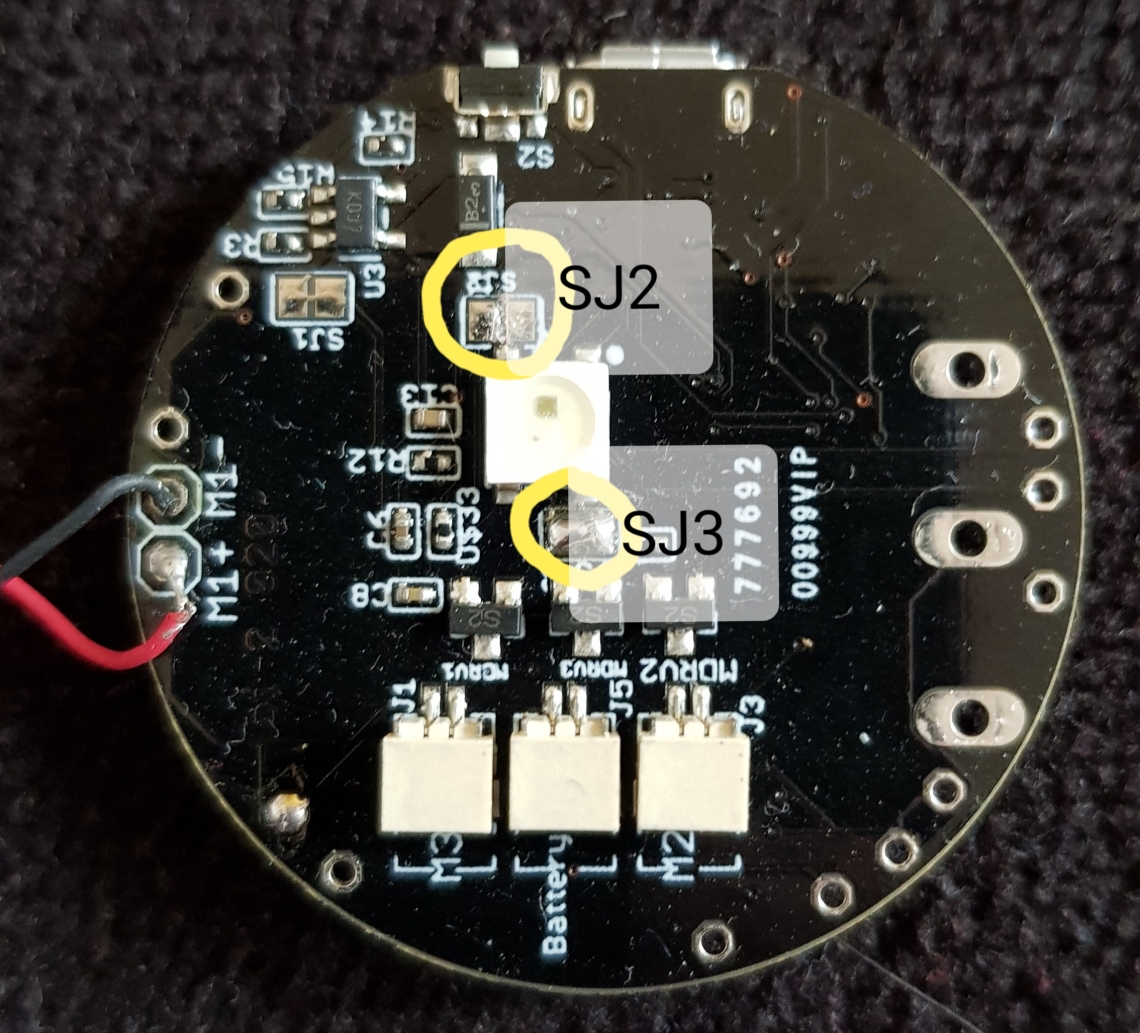

So I ordered two boards. The boards are round with a diameter of 5 cm (that’s the size of a wireless charging coil). As I had a coupon the two boards were only about 50US$. Including delivery! And even better: Seeedstudio delivers from a logistic company in Germany. So I had not to pay any taxes. Great. But… unfortunately … I made beginner’s mistakes…during design.

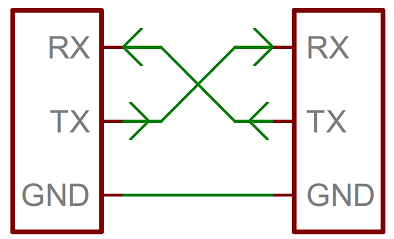

- Problem: As the board should be programmable by USB connection you need a USB to serial bridge eg. one of the FTDI ICs. This bridge has two important connections TX (transfer) and RX (receive). And the ESP8266 has the same TX and RX. But don’t connect them. Instead you have to connect RX to TX and vice versa. (Well I should have know, when I soldered null modems maybe 20 years ago or more…)

Taken from Sparkfun

- Problem: When using the serial monitor of the Arduino IDE you need another connection: RTS (ready to send). Unfortunately the used serial bridge – the FTDI FX230XS IC – had no RTS. (There is a circuit which works without RTS, but I didn’t know.)

- Problem: I used GPIO0 for driving the motor, that’s why auto reset doesn’t work. So I had to short-cut GPIO0 and GROUND for uploading a script.

So I tried to fix the problem. At first I had to cut the wrong connections. On the bottom side of the board the RX and TX wires are quit good accessible. So I could cut them using a dremel.

In the next step I had to connect the RX and TX headers of the FTDI chip with the ESP 8266…

The green clamps were used to shortcut another wrong connection.

Finally upload with the Arduino IDE was possible, but no debugging using the serial monitor. Battery charging seemed to work, too, although this needs more time for testing. WiFi worked. Essentially I could upload a script which made one LED blinking. And I could start the WiFi manager.

Debugging such a complex thing like a ESP8266 without serial connection is almost impossible. But then I found RealTerm. This is the only terminal program for Windows where you have all options to use or not use serial sync mechanisms like DTR, RTS etc. It is made to make a serial connection work even if you have only TX, RX and GROUND.

Here you can decide to ignore RTS and/or DTR by pressing “Clear”. (Read more about this here.)

.

And finally it worked. The ESP8266 sends debug text to the serial monitor. The transmission maybe scrambled, but it is still readable. Realterm – a really great tool for debugging serial connections.

Readings of the MPU9250 (accelerometer, gyro)

Probably it is more reasonable to use a bread board for the development of a design. But customizing an open source design on the PC and then get it assembled for a reasonable price – for me it’s like a dream come true. But as you see – all your efforts can be worthless.

But I will do it again…

But I will do it again…