Most cases for the body interaction vibration development boards so far had a “massage wand” style. This one is in form of a ring. Inside the ring is enough space for the vibration motor, pcb and LiPo. Work in progress! https://tinkercad.com/things/fcRz5yzJAXR http://www.thingiverse.com/thing:826715

Most cases for the body interaction vibration development boards so far had a “massage wand” style. This one is in form of a ring. Inside the ring is enough space for the vibration motor, pcb and LiPo. Work in progress! https://tinkercad.com/things/fcRz5yzJAXR http://www.thingiverse.com/thing:826715

Tag: BI1 case

Molding a silicone case for the BI1 board with a 3d printed form

As alternative to the 3d printed form a flexible form made with silicone could improve the handling of the body interaction board (BI1) for certain applications. The vibration is more comfortable and less noisy compared to other cases. If you want to do it on your own follow this how-to.

Some adult toys are made of silicone or at least are coated with silicone. Silicone cases are easy to clean.

We have constructed a 3D printed form where we will fill in the silicone. The form comes in two parts that have to be fixed to one another by tinkering wire. In addition the board has to be hooked to the form. For this we use a USB connector which is plugged in the USB port of the board. Then the USB connector is fastened to the form.

Use a silicone which will become solid after moulding. This property of silicone is indicated by the shore A value. Silcone with a low value is flexible. We use silicone with shore A 43.

Do you want to try it on your own? Follow this how-to and tell us your experience.

Happy new year!

Here is a green body interaction case printed by the Seeedstudio crew! BI is getting colourful! Thank to all supporters of the Indiegogo campaign. Get your body interaction case now! body interaction wishes a peaceful happy new year!

New case designs

Two new design for the body interaction 1 design are available at thingiverse. The “massive body” interaction case – it is the biggest one so far: http://www.thingiverse.com/thing:591477 And the smallest case (“mini”) in now available at http://www.thingiverse.com/thing:591418

Encasement printed with da Vinci 1.0 printer

The development of the encasement for the body interaction takes a lot of time although we use 3d print services. The 3d print services need one to four weeks until delivery. The quality of the cases are good, but if you wait so long for the next iteration of the design, it can’t be called rapid prototyping. Now we bought…

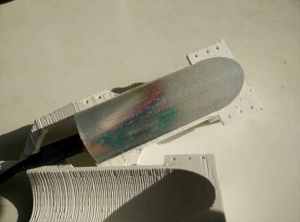

Comparing STL and SLS print technology

The encasement in the middle is printed in Stereolithography (STL) technology. In comparison the blue and red case is printed in polished Selective Laser Sintering (SLS). The STL encasement has a very smooth and soft surface and is even more solid than the polished SLS version.The STL looks rather matt compared to the shiny surface of the polished SLS print.…

BI1 case

This is a 3D printed case for the BI1.